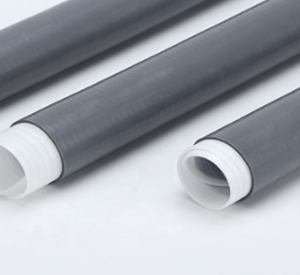

3:1 Dual Wall

◆ 4:1 Very high shrink ratio

◆ Continuous operating temperature: -55℃~ 125℃

◆ Shrink temperature: 120℃

- Description

- Inquiry

3:1 Dual Wall Adhesive-Lined Heat-Shrink Polyolefin Tubing

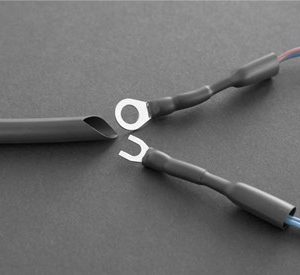

Adhesive lined heat shrink tubing with environmental sealing capability for a wide variety of

electrical applications, including automotive and marine wire harness, wire splices, breakouts, and connector-to-

cable transitions.

Features:

1. 3:1 shrink ratio

2. Longitudinal shrink ratio: ≤+8%

3. Out jacket flame retardant, inner adhesive self-extinguished

4. Super sealing against water, moisture or other contaminants

5. Continuous operating temperature: -55℃~ 125℃

6. Shrink temperature: 120℃

Dimensions:

| Size | As supplied | After recovery (mm) | Standard Package | |||

| Inch | mm | Internal Diameter(mm) | Inertnal Diameter | Total Wall Thickness | Wall Thickness of Adhesive | m/spool |

| 1/8 | 3.2 | 3.2 | 1.0 | 0.90±0.15 | 0.35±0.10 | 200 |

| 3/16 | 4.8 | 4.8 | 1.6 | 1.00±0.15 | 0.40±0.10 | 100 |

| 1/4 | 6.4 | 6.4 | 2.20 | 1.25±0.15 | 0.45±0.12 | 100 |

| 5/16 | 7.9 | 7.9 | 2.70 | 1.30±0.15 | 0.50±0.12 | 100 |

| 3/8 | 9.5 | 9.5 | 3.20 | 1.40±0.15 | 0.50±0.12 | 50 |

| 1/2 | 12.7 | 12.7 | 4.20 | 1.70±0.15 | 0.50±0.12 | 36.6 |

| 5/8 | 15.0 | 15.0 | 5.20 | 1.80±0.15 | 0.55±0.15 | 30.5 |

| 3/4 | 19.1 | 19.1 | 6.30 | 1.95±0.15 | 0.55±0.15 | 30.5 |

| 1 | 25.4 | 25.4 | 8.50 | 2.05±0.20 | 0.55±0.15 | 30.5 |

| 1- 1/4 | 30.0 | 30.0 | 10.20 | 2.20±0.20 | 0.60±0.15 | 24.4 |

| 1- 1/2 | 39.0 | 39.0 | 13.50 | 2.50±0.20 | 0.60±0.15 | 18.3 |

| 2 | 50.0 | 50.0 | 17.00 | 2.80±0.25 | 0.70±0.15 | 12.2 |

| 5/2 | 64 | 64 | 21.00 | 3.00±0.25 | 0.70±0.15 | 6.1 |

| 3 | 75 | 75 | 25.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

| 7/2 | 90 | 90 | 30.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

| 4 | 100 | 100 | 34.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

| 5 | 125 | 125 | 42.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

Technical Data:

| Test Item | Test Method | Test Result |

| Tensile Strength(Mpa) | ASTM D2671 | ≥10.4 |

| Elongation% | ASTM D2671 | ≥300 |

| Tensile Strength afterAging (Mpa) | UL 224 158×168hr | ≥7.3 |

| Elongation after Aging% | UL 224 158℃×168hr | ≥200 |

| Dielectric Strength | IEC 243 | ≥ 15 |

| Volume Resistance(Ω.cm) | ASTM D876 | ≥ 1014Ω.cm |

Hot Melting Adhesive Property

| Test Item | Test Method | Test Result |

| Water absorption ratio: | ASTM-D570 | <0.2% |

| Softing point | ASTM-E8 | 95℃ |

| Strength of pearing(PE) | ASTM-D1000 | 120N/25m |

| Strength of pearing(AL) | ASTM-D1000 | 80N/25m |